Textile innovations are transforming one of the oldest and most dynamic sectors—reshaping the modern textile industry in unprecedented ways. As of 2024, advancements in textile manufacturing have introduced cutting-edge technologies, materials, and processes that significantly enhance efficiency, sustainability, and creativity. From smart textiles to sustainable manufacturing techniques, the industry is revolutionising, creating exciting opportunities for manufacturers, designers, and consumers. This blog delves into the latest trends and innovations in the textile industry, presenting updated data and highlighting the key services offered by Rawalwasia Group.

Textile Innovations Leading the Modern Textile Industry

Cutting-edge technologies are redefining how fabrics are produced, used, and perceived through innovations in textile manufacturing. Below are some of the most impactful innovations driving the modern textile industry:

- Smart Textiles: Also known as e-textiles, smart textiles are fabrics embedded with sensors and conductive fibres. These textiles can monitor body vitals, adjust temperature, or even charge devices. For instance, athletes benefit from smart sportswear that tracks performance metrics.

- 3D Knitting and Printing: 3D knitting and printing technologies have streamlined the production of customised and seamless garments. This innovation minimises fabric waste, contributing to sustainable manufacturing.

- Sustainable Textiles: The push for sustainability has led to the developing of eco-friendly fabrics like organic cotton, bamboo, and recycled polyester. According to a report by the International Textile Manufacturers Federation (ITMF), 65% of global textile manufacturers will have adopted sustainable practices in 2024.

- Nanotechnology in Textiles: Nanotechnology enhances fabric properties, making them water-repellent, wrinkle-free, or antibacterial. This is particularly significant for medical and protective clothing.

- Artificial Intelligence (AI) and Automation: AI is transforming the industry by optimising quality control, supply chain management, and inventory forecasting. Automated sewing robots and pattern-cutting machines have reduced production times significantly.

- Digital Printing: Digital textile printing allows for vibrant and intricate designs without traditional screens or dyes. This technology saves water and ink, aligning with environmental goals.

Current Trends in the Modern Textile Industry

Focusing on sustainability, efficiency, and innovation characterises the modern textile industry in 2024. Some key trends include:

- Circular Economy Models: Many textile companies are adopting circular economy practices, such as recycling old garments into new ones, to reduce waste and conserve resources.

- On-Demand Manufacturing: The rise of on-demand manufacturing allows companies to produce garments based on real-time consumer demand, reducing overproduction and inventory costs.

- Integration of IoT in Textile Manufacturing: IoT devices enable real-time machinery monitoring, improving efficiency and minimising downtime.

- Biodegradable Fabrics: In 2024, the development of biodegradable textiles, such as fabrics made from algae or mushroom-based materials, is gaining traction.

Global Textile Market Growth: Emerging markets are driving increasing demand, and experts expect the global textile market to reach $1.2 trillion by 2024.

Key Services by Rawalwasia Group in Textile Innovations

Rawalwasia Group stands out as a leader in the textile manufacturing sector, offering a range of innovative services that cater to modern industry demands. With a solid commitment to quality, efficiency, and sustainability, the group provides:

- Yarn and Fabric Manufacturing: Rawalwasia uses advanced spinning and weaving technologies to produce high-quality yarns and fabrics suitable for diverse applications.

- Textile Dyeing and Finishing: The group employs eco-friendly dyeing processes that minimise water usage and ensure vibrant, long-lasting colours.

- Customised Solutions: Rawalwasia tailors its offerings to meet specific customer needs, from smart textiles to sustainable fabrics, ensuring optimal satisfaction.

- Supply Chain Optimization: Leveraging AI and IoT, Rawalwasia ensures efficient inventory management and timely delivery of products.

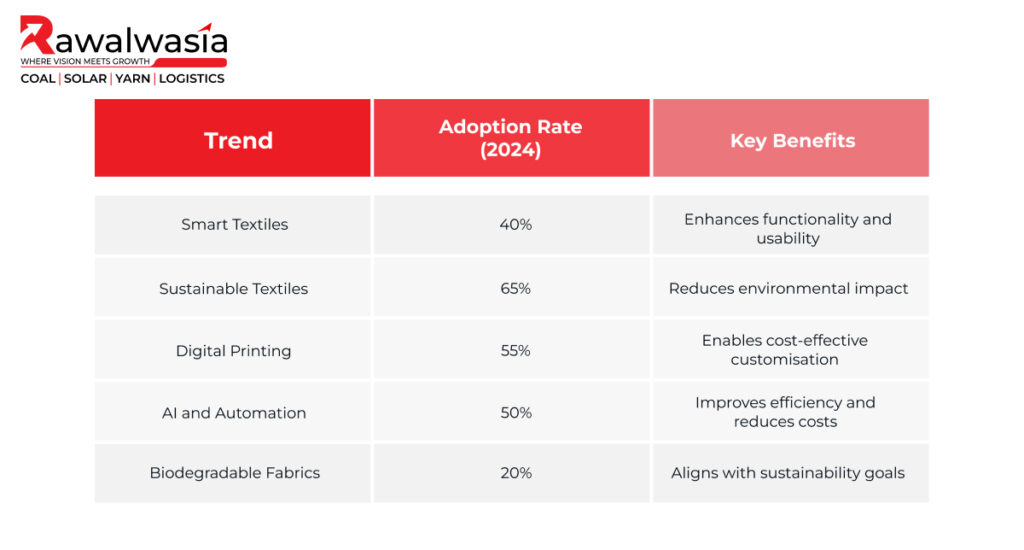

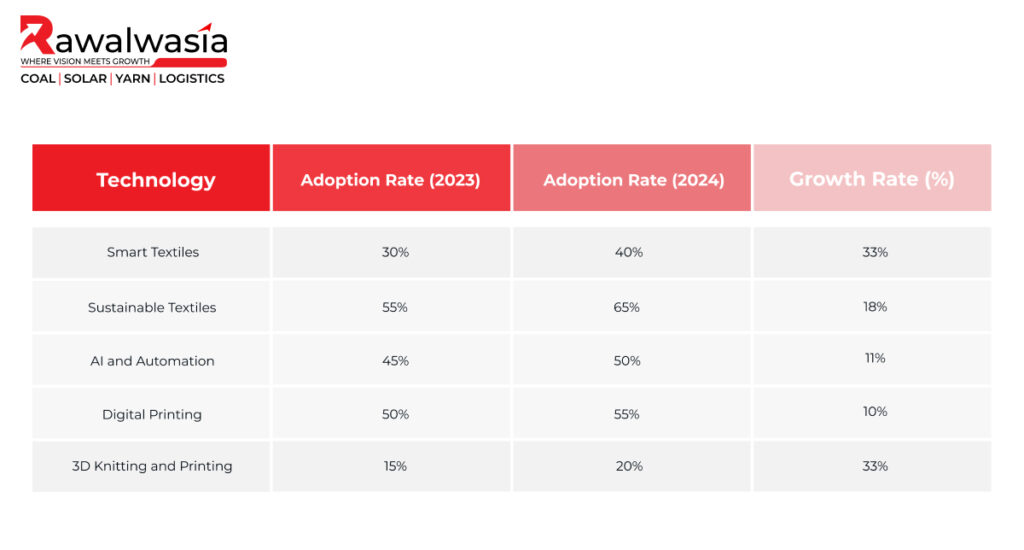

Data on Innovations in Textile Manufacturing (2024)

The latest industry statistics show the growth and adoption of textile innovations. The following graph illustrates the adoption rates of key technologies in textile manufacturing:

The data reflects the rapid integration of innovative technologies, highlighting the industry’s shift toward sustainability and efficiency.

Conclusion

The textile industry in 2024 will be a hub of innovation driven by technological advancements and a commitment to sustainability. From smart textiles and AI-powered manufacturing to sustainable fabrics and digital printing, the modern textile industry is transforming to meet the demands of a dynamic market. These innovations improve efficiency and align with global goals of reducing environmental impact and enhancing functionality.

With its wide range of services, Rawalwasia Group plays a pivotal in advancing textile manufacturing. The group sets quality and innovation benchmarks by adopting cutting-edge technologies and sustainable practices. Whether producing high-quality yarns, offering customised fabric solutions, or optimising supply chains, Rawalwasia Group exemplifies excellence in the modern textile industry.

As the industry evolves, staying updated on the latest trends and technologies will be crucial for manufacturers, designers, and consumers. With its focus on textile innovations and commitment to quality, the modern textile industry is poised for a promising future, delivering sustainable and high-performance solutions to meet the needs of a changing world.